Extensive mechanical & electrical checks are performed on all products during the final inspection process in which the approved drawings are used for validation. Rigorous mechanical stresses are applied to test leads in order to reveal any weaknesses in product construction. Depending on specification, various electrical tests such as continuity and resistance are checked before despatch. In some circumstances, the product will be studied for Failure Mode Effect & Analysis. Final inspection validation procedures ensure the product is built to specification & performs within the parameters requested by the end user.

- Electrical Continuity Test

- Resistance Test

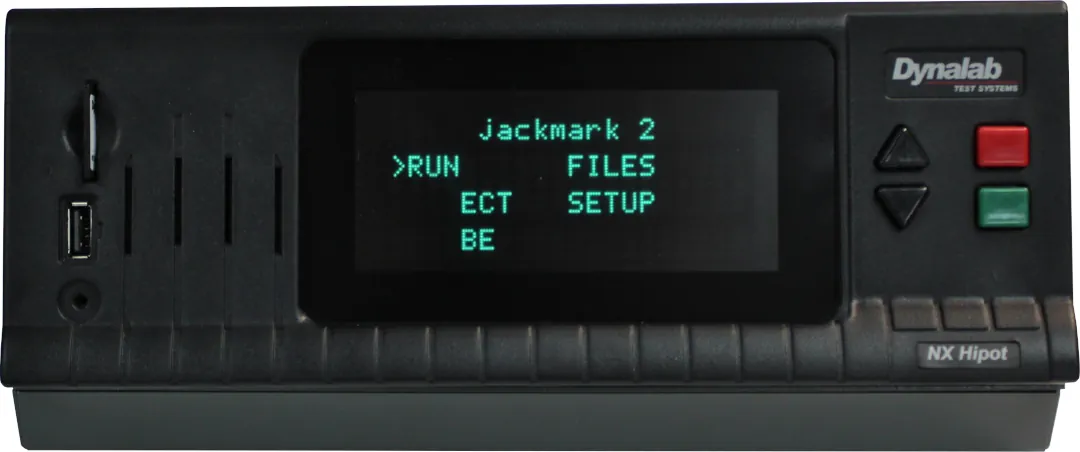

- HI-POT Test

- Vacuum Seal Detection Test

- Colour Recognition Test

- Bent Pin Detection

- Connector Presence Check

- Pneumatic Catch-Release Check

- LED Illumination Check